It might be useful for people to ask for advice on small things we run into while doing different projects. We might already have one, but we don't seem to have any posts addressing my current situation.

Last week, an old friend asked if I'd be interested in a free instrument...but I need to fix it. Its primary issue is a pickup-mounting machine screw that's been broken off in the body. The screw shaft is nearly flush with the part of the body it threads into, and I have maybe 3/32" of surface area showing. So I need to extract this thing.

It looks like my options are pretty much one of these:

1) Buy a screw extraction kit, drill a ways into that shaft, pound the extractor in there, and turn it counter-clockwise. Sounds good...but I don't have a screw head for more surface area. I just have the screw shaft, which offers little real estate to work with. Does anyone even make a screw extractor that small?

2) Maybe...Dremel a channel in the top of the screw shaft, enough to turn it with a flat-head screwdriver. (I can easily envision the Dremel tool slipping off the screw and scoring up the rest of the surface.)

3) Just drill the thing out. I have a few friends with drill presses, so I'd imagine I'd just slowly obliterate the shaft that's in there.

Complicating wrinkle: the screw's stuck in some kind of plastic, rather than wood. My guess is that the plastic's threaded inside the hole, which isn't great. The other screw for the pickup came right out, though there's a divot around its hole, which suggests the plastic isn't particularly robust. But still, free instrument.

What are people's experience with extracting broken screws/bolts?

Re: Thread of How-To Questions

2That particular bit?Maurice wrote: Sat Jan 06, 2024 4:44 pm It might be useful for people to ask for advice on small things we run into while doing different projects. We might already have one, but we don't seem to have any posts addressing my current situation.

Last week, an old friend asked if I'd be interested in a free instrument...but I need to fix it. Its primary issue is a pickup-mounting machine screw that's been broken off in the body. The screw shaft is nearly flush with the part of the body it threads into, and I have maybe 3/32" of surface area showing. So I need to extract this thing.

It looks like my options are pretty much one of these:

1) Buy a screw extraction kit, drill a ways into that shaft, pound the extractor in there, and turn it counter-clockwise. Sounds good...but I don't have a screw head for more surface area. I just have the screw shaft, which offers little real estate to work with. Does anyone even make a screw extractor that small?

2) Maybe...Dremel a channel in the top of the screw shaft, enough to turn it with a flat-head screwdriver. (I can easily envision the Dremel tool slipping off the screw and scoring up the rest of the surface.)

3) Just drill the thing out. I have a few friends with drill presses, so I'd imagine I'd just slowly obliterate the shaft that's in there.

Complicating wrinkle: the screw's stuck in some kind of plastic, rather than wood. My guess is that the plastic's threaded inside the hole, which isn't great. The other screw for the pickup came right out, though there's a divot around its hole, which suggests the plastic isn't particularly robust. But still, free instrument.

What are people's experience with extracting broken screws/bolts?

On a "Free..." instrument?

If I thought the instrument had potential, I'd think about putting what I did not have to pay for it into having a trustworthy shop address the issue you are describing.

Re: Thread of How-To Questions

3There's this option: https://www.rockler.com/screw-extractor ... zuEALw_wcB

It works great and you'll need to have a matching plug to fill the hole.

It works great and you'll need to have a matching plug to fill the hole.

Re: Thread of How-To Questions

4Harbor freight sells Lefty drill bit sets. I got a headless machine screw about that size out using them. I think the set was like $7 when i bought it.

Re: Thread of How-To Questions

5If it's in plastic, could you heat the end with a soldering iron to soften the grip, before turning it with some grips on whatever is protruding from the body?

Re: Thread of How-To Questions

6I've never had luck with extractor kits/bits myself, but you might get lucky. If the screw is indeed threaded into some kind of plastic receiver that's mounted into the wood, the good news is that it's probably going to be easier to turn than if it was just biting into the wood itself. I would try Matt's suggestion first. You could also try carefully removing some more of the plastic material at the surface level with an exacto or something to get more of the screw exposed. Then you can try to lock a vice grips on the tip of the exposed post and hope it unscrews.

Radio show https://www.wmse.org/program/the-tom-wa ... xperience/

My band https://redstuff.bandcamp.com/

Solo project https://tomwanderer.bandcamp.com/

My band https://redstuff.bandcamp.com/

Solo project https://tomwanderer.bandcamp.com/

Re: Thread of How-To Questions

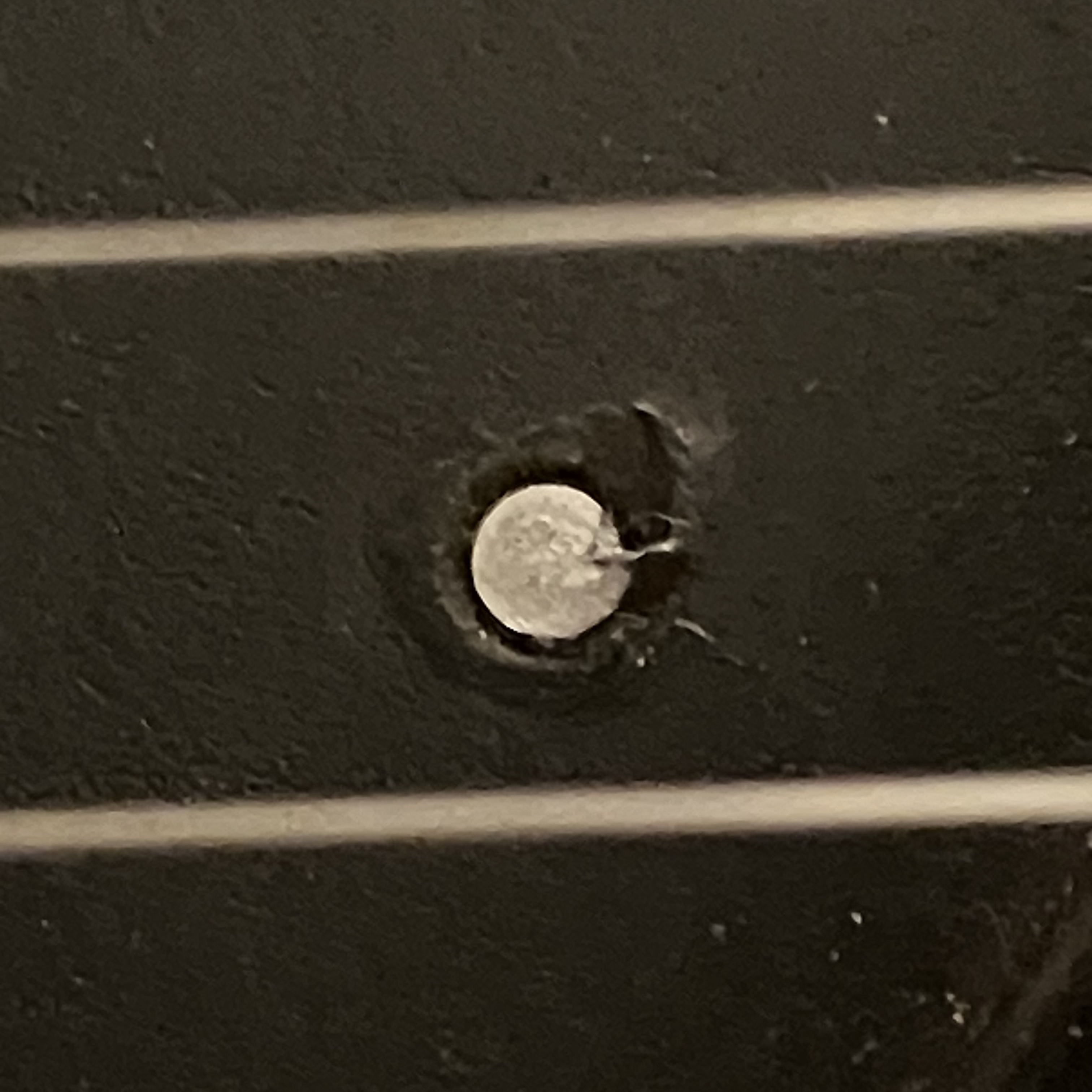

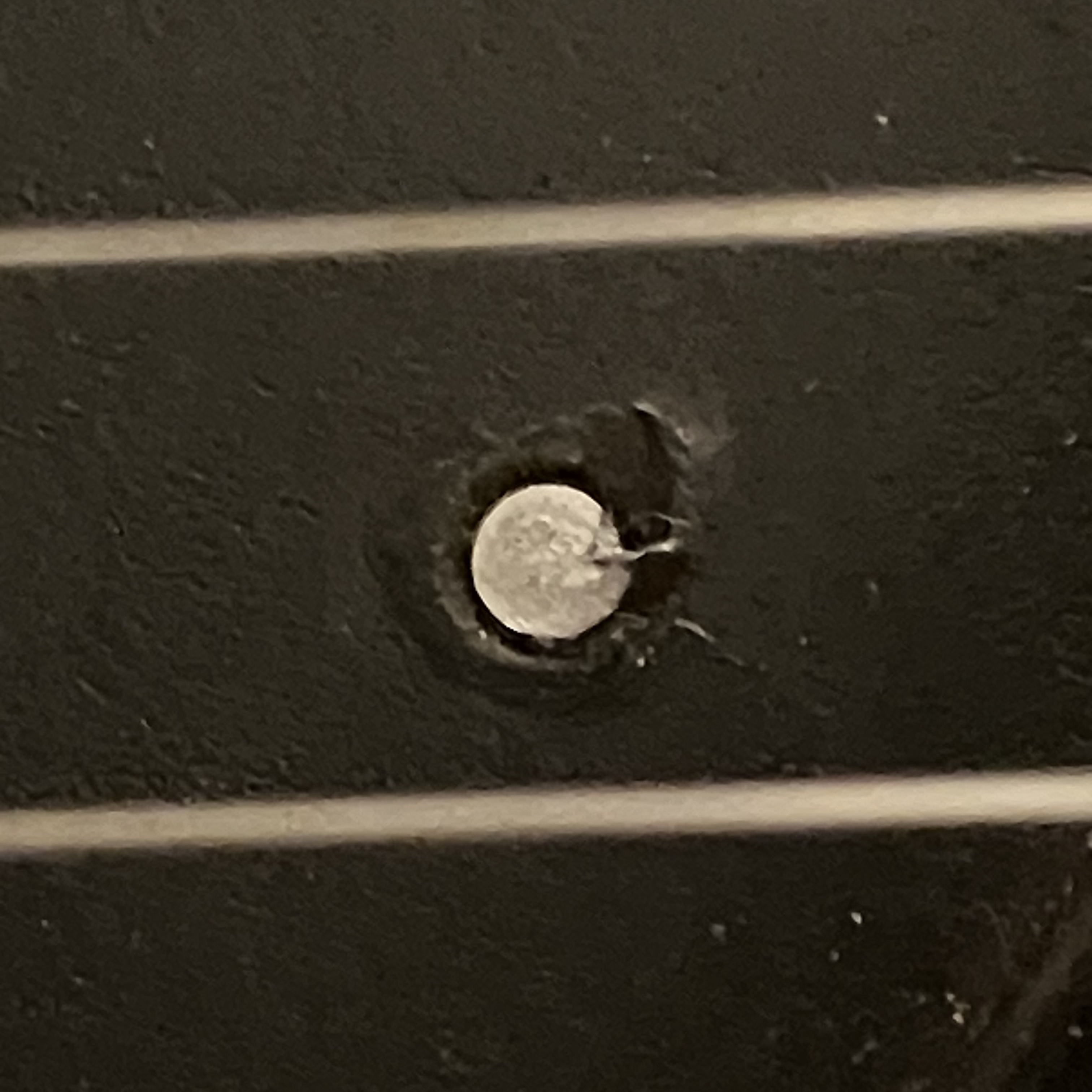

7Thank you, everyone! I'm leaning toward Dremeling a slot in there to try to unscrew it. It's currently broken off flush, so I can get more options as I get something above the surface. Here's a zoomed-in photo from the top (through a couple strings, before I took them off).

So yeah, right into the plastic. That makes me reluctant to do the around-the-hole extraction and plug replacement. If I can get a bit of traction on it, then I could leave the threaded hole and surrounding material. (Going to have to order the right Dremel attachment, though--the local chain supposedly had two in stock, but nothing on the shelf yesterday.)

So yeah, right into the plastic. That makes me reluctant to do the around-the-hole extraction and plug replacement. If I can get a bit of traction on it, then I could leave the threaded hole and surrounding material. (Going to have to order the right Dremel attachment, though--the local chain supposedly had two in stock, but nothing on the shelf yesterday.)

Re: Thread of How-To Questions

8Another cheap option is, if you can drill a small hole into it (use a metal bit and lubricate with oil if you can) then you can hammer a slightly larger Allen key into the hole and it will jam enough that you can use it to turn the screw stump. Obviously this involves sacrificing the Allen key but you may well have half a dozen of the saddle-height-adjusting size kicking around. If you really want some leverage, hammer in the short-arm end.

Re: Thread of How-To Questions

10Ah, I may end up doing that if the slot doesn't work out!matttkkkk wrote: Another cheap option is, if you can drill a small hole into it (use a metal bit and lubricate with oil if you can) then you can hammer a slightly larger Allen key into the hole and it will jam enough that you can use it to turn the screw stump. Obviously this involves sacrificing the Allen key but you may well have half a dozen of the saddle-height-adjusting size kicking around. If you really want some leverage, hammer in the short-arm end.

That'll ruin the resale value...or would it?